Platform

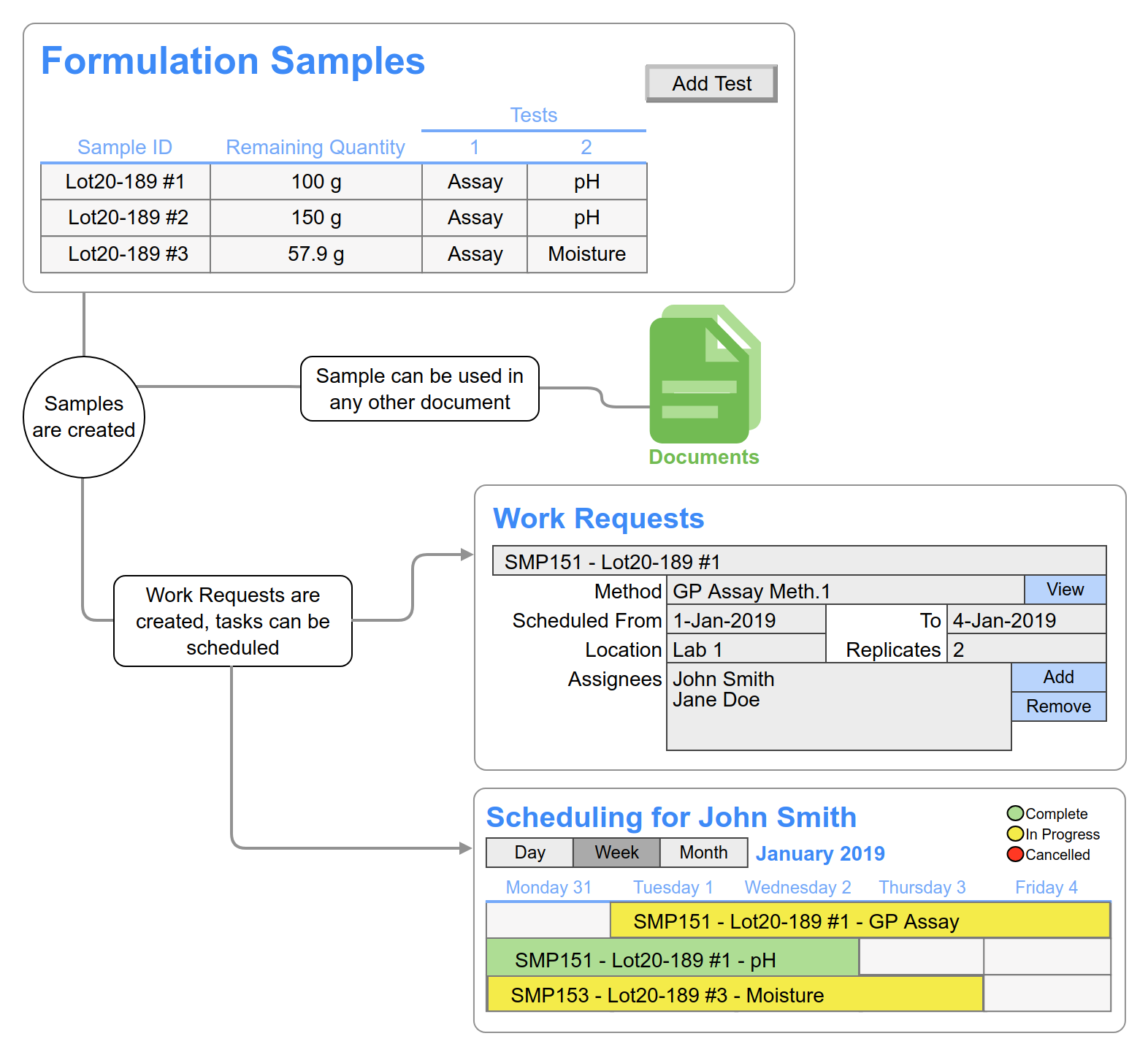

Our Lab Informatics platform combines the utility of a LIMS and versatility of an ELN

Top Features

Solutions

Looking for something more specific? Read through the other solutions we support out of the box

Resources

Browse our archive of case studies, functional documentation, and announcements.

Looking for something specific? Search our site:

temp text